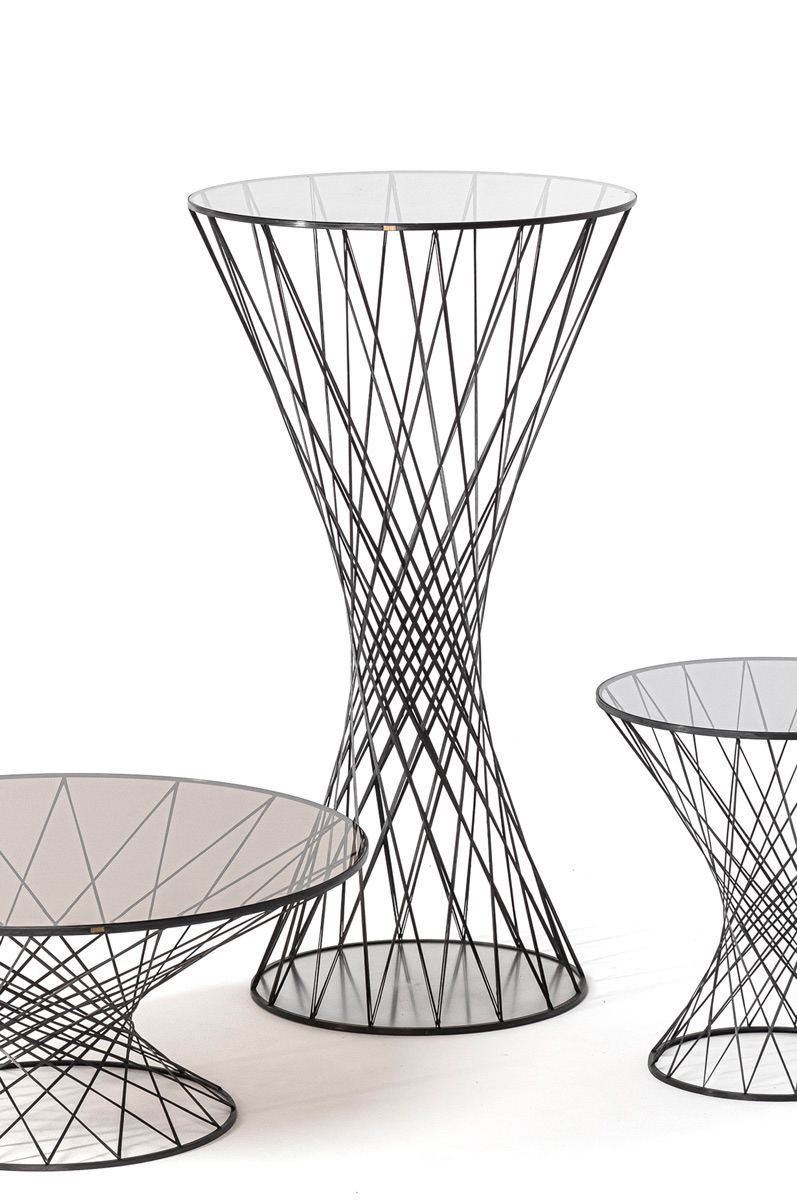

LINITY. Design studio and manufactory for carbon fibre furniture based in Stuttgart, Germany. Founded by the two architects Jakob Weigele and Manuel Scholz, who specialise in innovative carbon fibre products.

Unique is the manufacturing process, which has found its inspiration in nature and is perfected in an automated form fitting.

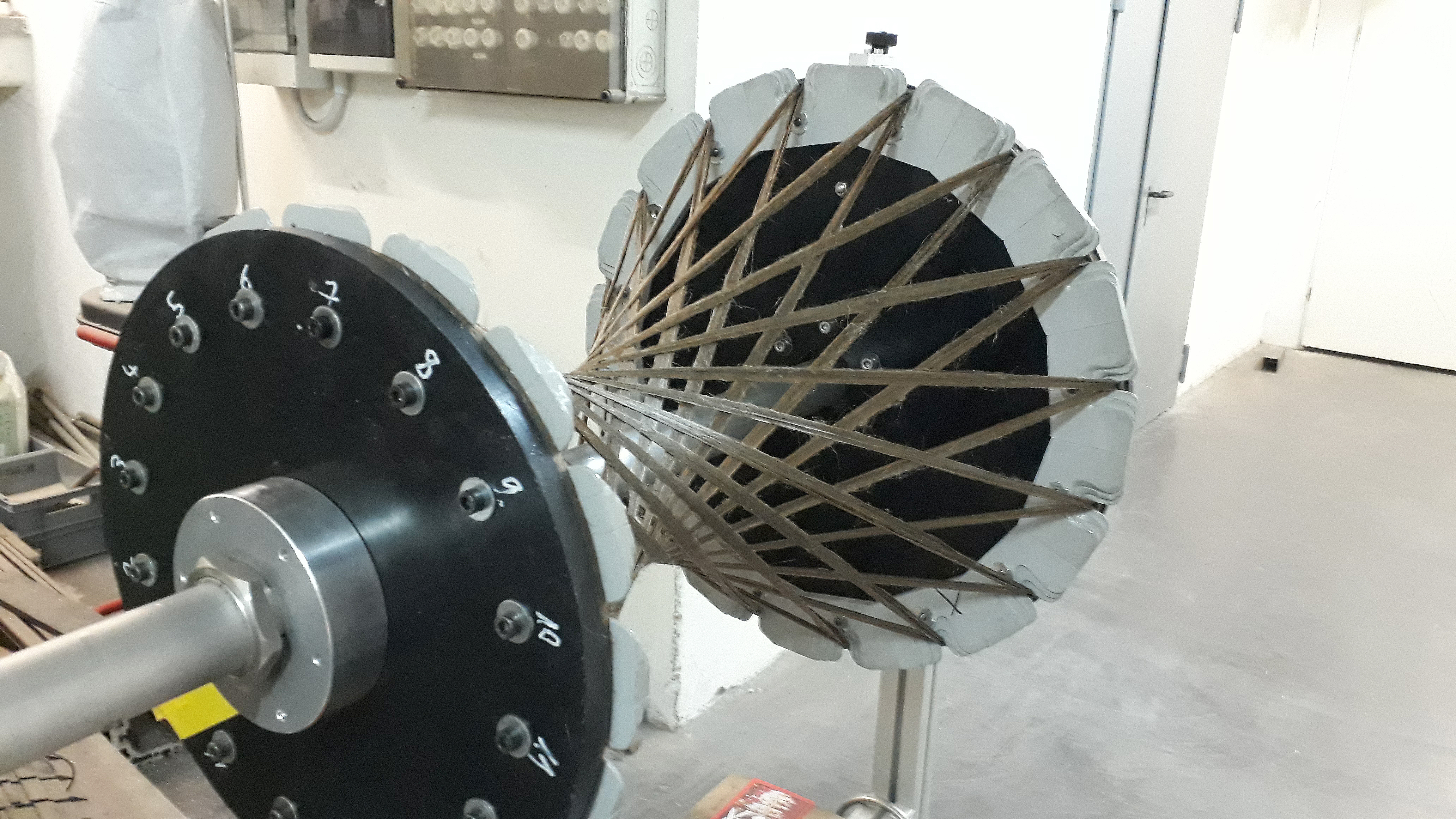

The story began with a research project on new manufacturing methods based on the ingenious construction of the lobster shell. The idea was to develop a robot for winding carbon fibres that would sit and work on this basis. The resulting structure was made of carbon and glass fibres. It led to great success and was presented worldwide.

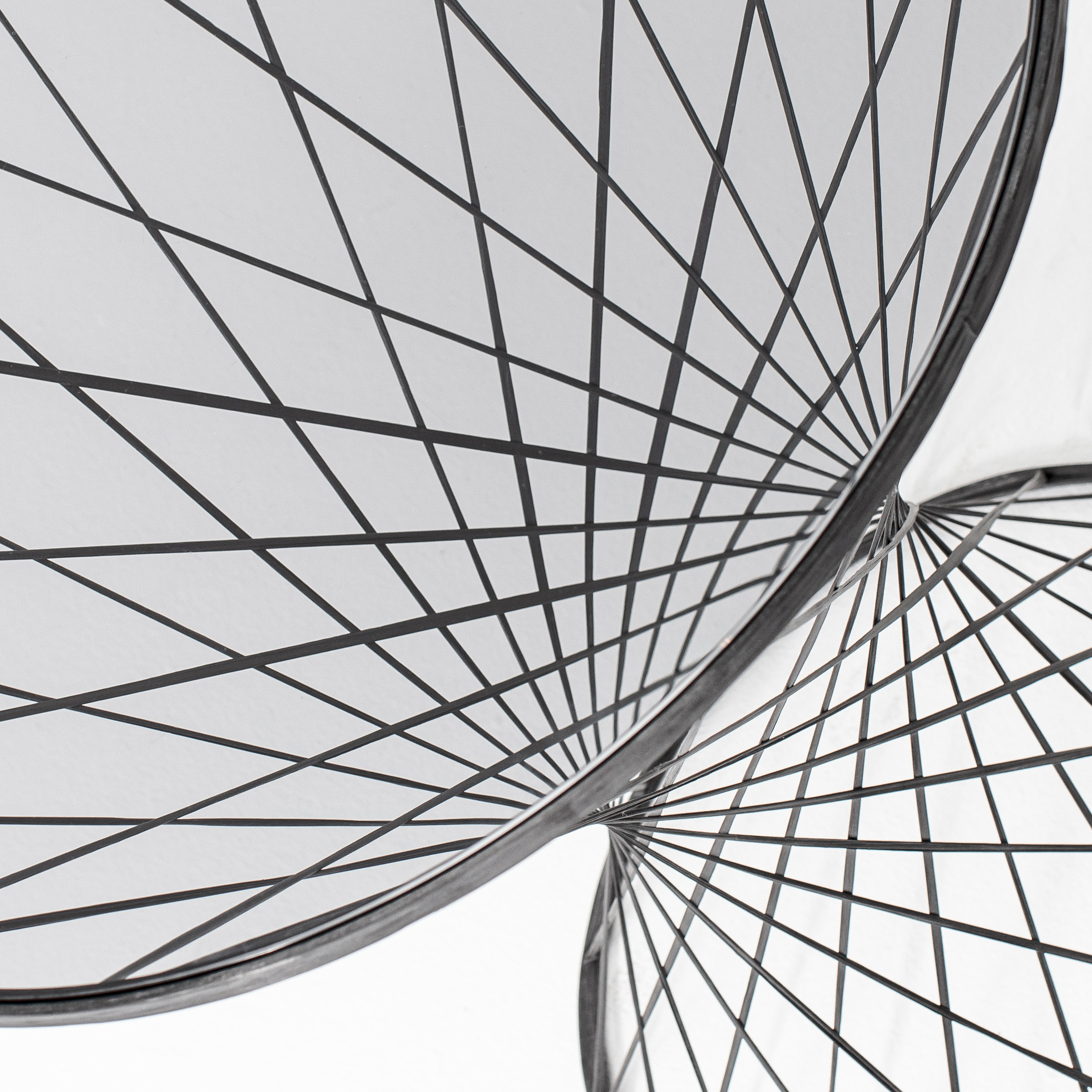

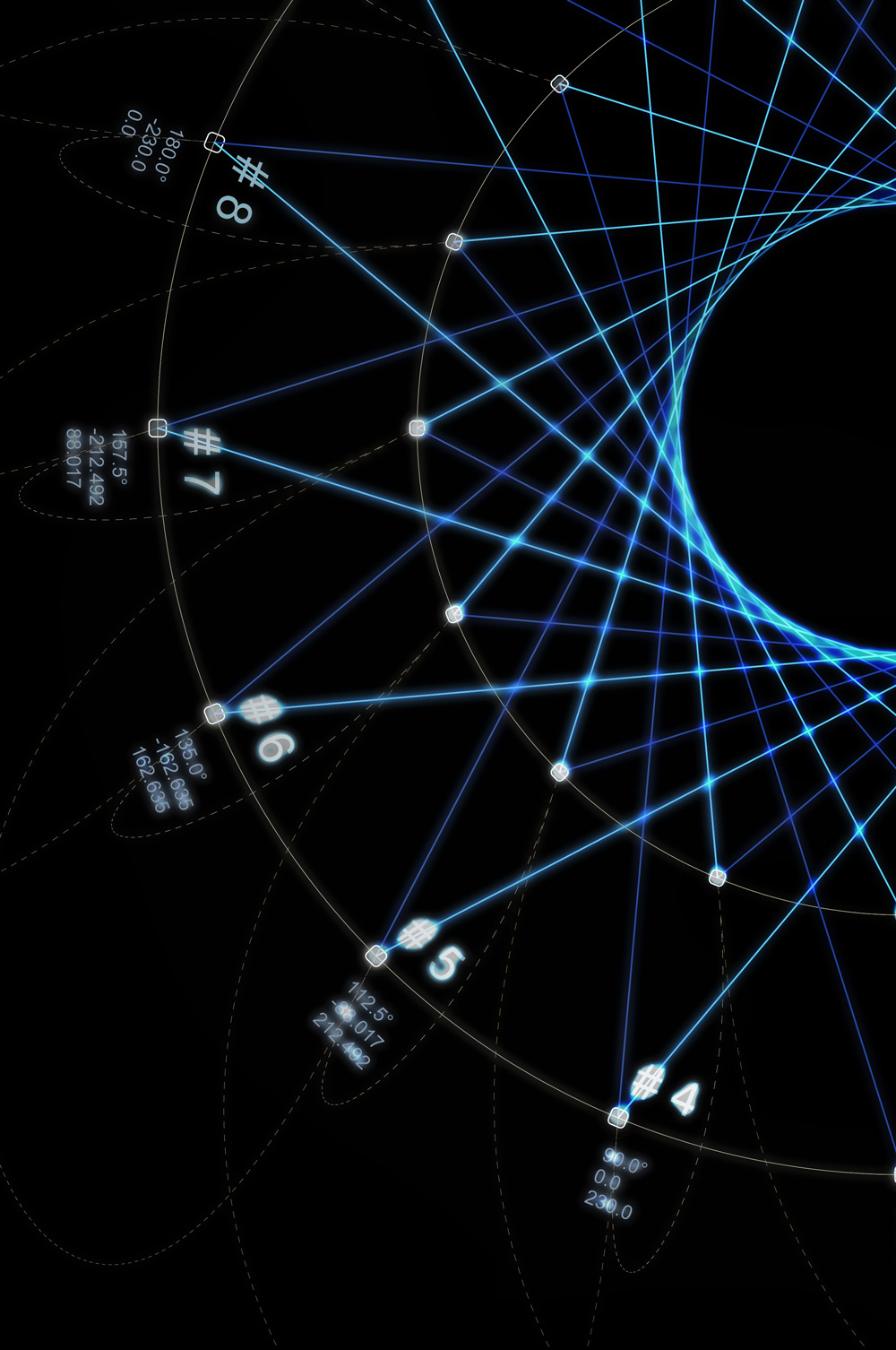

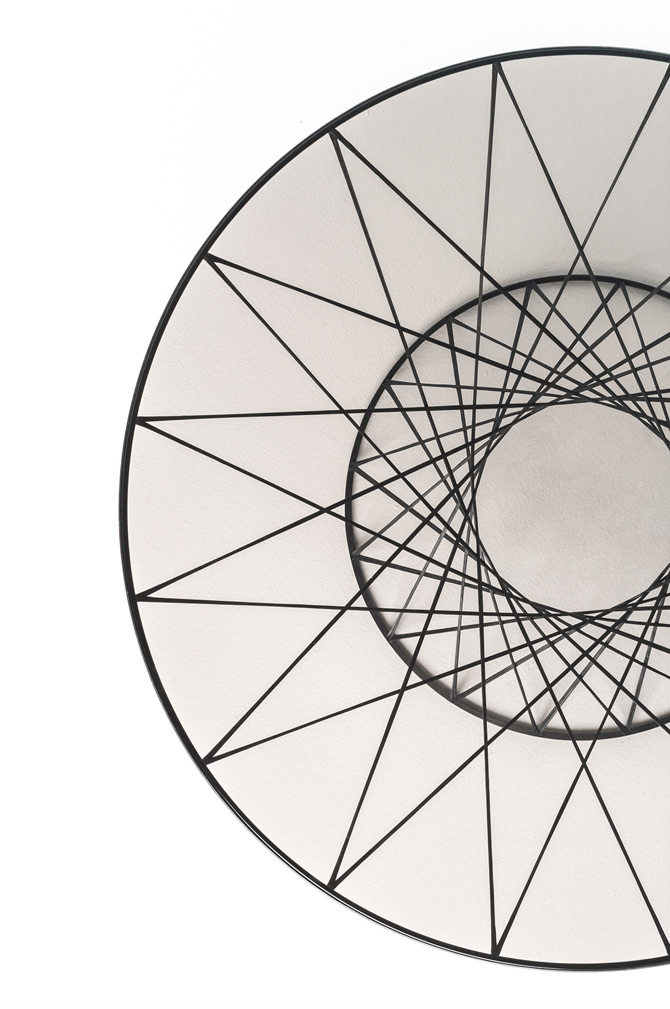

Breaking down the design of the product, the base is the table circle, its diameter, the height and the fibre spacing. This leads to a simple hyperbolic geometry. However, once the fibres cross, the geometry changes according to the forces between the fibres due to the coreless production design. The result is a natural and unique design.

Ultimately, the product represents an innovative and efficient manufacturing method with a high-performance material that has the main influence on the geometry. The result is a unique and exceptional design, exciting and harmonious at the same time, down to the smallest detail.

The entire product is wound with a continuous carbon fibre roving. In this way, it is achieved that no carbon fibres are wasted during production.

Material.

We are specialised in processing all kinds of fibre materials. Only the raw fibres are used as rovings. Layer by layer, the fibres are wound into an endless loop and form the product into an object that integrates all aspects of functionality and design. No fibre material is wasted within the manufacturing process!

Process.

Our manufacturing process combines quality craftsmanship with innovation. The process leads to our unique and rough design, which incorporates our philosophy of transparency and honesty into the product. This is also in perfect harmony with the great connection between manufacturing and material properties.

Integration.

Our products are characterised by a close relationship between design, material and process. These manufacturing principles can also be found in nature. They lead to efficient design, maximum utilisation of material properties and flexible manufacturing.